In the blistering world of logistics, moving fast without wasting time is everything. Rugged, built-in industrial computers are now shaking up warehouses, boosting automation, sharpening inventory control, and making team communication smoother. In this post, well explore exactly how these tough little machines push warehouse productivity and why any modern supply chain should rely on them.

Once these computers sit inside a warehouses system, the perks pile up. For starters, they crunch data the moment it happens, so stock numbers and order progress are updated instantly. That lightning-speed picture of what is on hand helps managers trim surplus goods and dodge empty shelves. Because of that accuracy, turnover speeds up, costs drop, and customers leave with the right products at the right time.

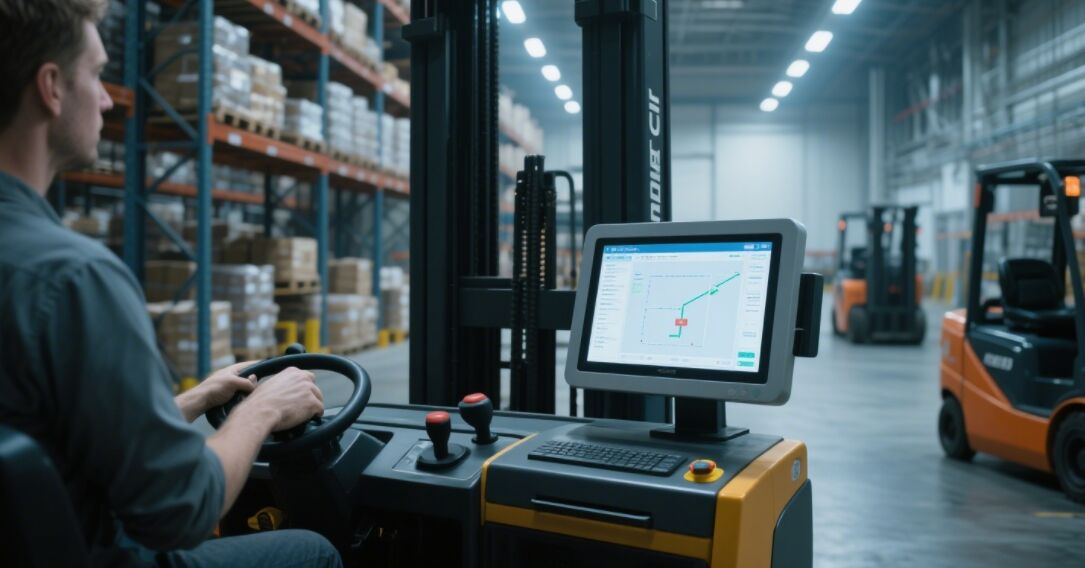

Embedded industrial computers are now at the heart of almost every automated warehouse task. Whether its an automated guided vehicle (AGV) or a robotic picking arm, these tiny powerhouses act like the main brain that runs the whole show. They talk to each other, to robots, and even to RFID tags so everything moves in step and nothing gets stuck. For example, the moment a team member scans a box for shipping, the embedded unit pings the inventory system, updates stock, and cuts the chance of a counting mistake.

These rugged computers also double as the warehouses digital chat room. They link scales, scanners, printers, and cameras all on the same network so everyone upstairs and down can see what is happening. When a rush order comes in or a truck is delayed, crew members get real-time alerts and can act without waiting for a slow paper trail. That speed is critical in a fast-moving market where customers expect their goods yesterday, not next week.

Embedded industrial computers are tough little powerhouses, so they fit right in with the high-pressure, fast-paced life of a busy warehouse. Built to handle the heat-literally-these units shrug off extreme cold, clouds of dust, and the occasional splash. Because they rarely crash or freeze, managers enjoy longer shifts with fewer interruptions, and that extra uptime translates directly into higher output.

Looking forward, warehouses will keep pushing toward full automation, and those same rugged computers will be at the wheel steering the change. As chips get faster and software smarter, expect new tools that trim wasted seconds and spotlight every bottleneck. When onboard AI and machine-learning algorithms read bar codes and study past seasons, they can alert staff to stock shortages before shelves run bare and even suggest reorder quantities on their own.

All things considered, embedded industrial computers have already started reshaping the way goods move from dock to aisle. By crunching data in the moment, automating routine chores, linking equipment through secure wireless channels, and standing up to grit and grime, they pay for themselves many times over. Companies that lean into these sturdy, smart systems will hold the upper hand in a marketplace that never stops demanding more speed and accuracy.